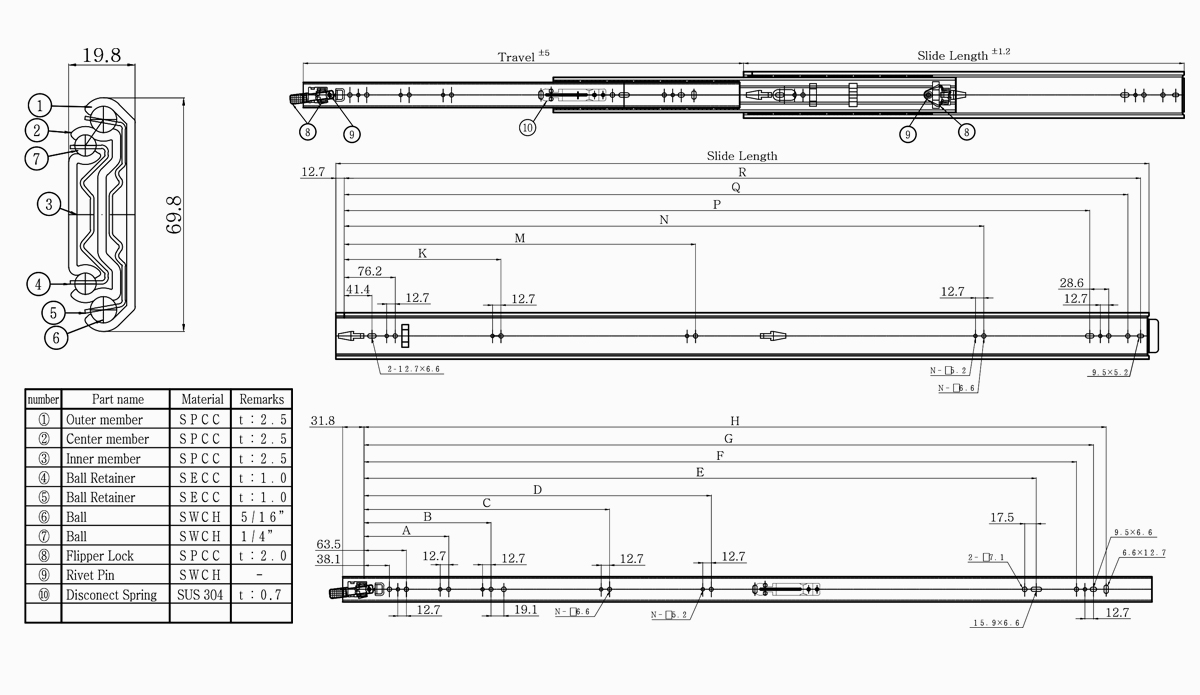

C698CL SERIES

| Features |

| - Product are common to the left and right |

| Recommended screws |

| - M5 or M6 truss bind machine screw |

| Grease |

| - JX Nippon Oil & Mineral Epniock AP (N) 2 |

| Surface Treatment |

| - Number (1), (2), (3) Electrogalvanized (Trivalent gloss chromate) |

| Part No. | Slide length (mm) |

Travel (mm) |

Mounting hole (mm) ± 0.8 mm | Rated Load (pair) |

||||||||

| A | B | C | D | E | F | G | H | (N) | (Kg) | |||

| 14 | 355.6 | 304.8 | - | - | - | - | - | - | 255.5 | 274.6 | 1765 | 180 |

| 16 | 406.4 | 406.4 | - | - | - | - | - | - | 306.3 | 325.4 | 1765 | 180 |

| 18 | 457.2 | 457.2 | 127.0 | - | - | - | - | - | 331.7 | 350.8 | 1765 | 180 |

| 20 | 508.0 | 508.0 | 127.0 | - | - | - | - | 357.1 | 382.5 | 401.6 | 1961 | 200 |

| 22 | 558.8 | 558.8 | 127.0 | 190.5 | - | - | - | 407.9 | 433.3 | 452.4 | 1961 | 200 |

| 24 | 609.6 | 609.6 | 127.0 | 190.5 | - | - | - | 458.7 | 484.1 | 503.2 | 1961 | 200 |

| 26 | 660.4 | 660.4 | 127.0 | 190.5 | - | - | 449.3 | 509.5 | 534.9 | 553.9 | 1863 | 190 |

| 28 | 711.2 | 711.2 | 127.0 | 190.5 | - | - | 500.1 | 560.3 | 585.7 | 604.8 | 1863 | 190 |

| 30 | 762.0 | 762.0 | 127.0 | 190.5 | - | - | 550.9 | 611.9 | 636.5 | 655.6 | 1863 | 190 |

| 32 | 812.8 | 812.8 | 127.0 | 190.5 | - | - | 601.7 | 661.9 | 687.3 | 706.4 | 1863 | 190 |

| 34 | 863.6 | 863.6 | 127.0 | 190.5 | - | 520.7 | 652.5 | 712.7 | 738.1 | 757.1 | 1863 | 190 |

| 36 | 914.4 | 914.4 | 127.0 | 190.5 | - | - | 703.3 | 763.5 | 788.9 | 807.9 | 1863 | 190 |

| 40 | 1016.0 | 1016.0 | 127.0 | 190.5 | 368.3 | - | 804.9 | 865.1 | 890.5 | 909.5 | - | - |

| 42 | 1066.8 | 1066.8 | 127.0 | 190.5 | 368.3 | - | 855.7 | 915.9 | 941.3 | 960.4 | - | - |

| 48 | 1219.2 | 1219.2 | 127.0 | 190.5 | 368.3 | 520.7 | 1008.1 | 1068.3 | 1093.7 | 1112.8 | - | - |

| 60 | 1524 | 1524 | 127.0 | 190.5 | 368.3 |

520.7 | 1312.9 | 1373.1 | 1398.5 | 1417.8 | - | - |

| Part No. | Slide length (mm) |

Travel (mm) |

Mounting hole (mm) ± 0.8 mm | Rated Load (pair) |

|||||||

| J | K | M | N | P | Q | R | (N) | (Kg) | |||

| 14 | 355.6 | 304.8 | - | - | - | 254.0 | 311.2 | 330.2 | 1765 | 180 | |

| 16 | 406.4 | 406.4 | - | - | - | 304.8 | 361.9 | 381.0 | 1765 | 180 | |

| 18 | 457.2 | 457.2 | - | - | - | 355.6 | 412.8 | 431.8 | 1765 | 180 | |

| 20 | 508.0 | 508.0 | - | - | - | 406.4 | 463.6 | 482.6 | 1961 | 200 | |

| 22 | 558.8 | 558.8 | - | - | - | 457.2 | 514.4 | 533.4 | 1961 | 200 | |

| 24 | 609.6 | 609.6 | - | - | - | 508.0 | 565.2 | 584.2 | 1961 | 200 | |

| 26 | 660.4 | 660.4 | - | - | - | 558.8 | 615.9 | 635.0 | 1863 | 190 | |

| 28 | 711.2 | 711.2 | - | - | - | 609.6 | 666.8 | 685.8 | 1863 | 190 | |

| 30 | 762.0 | 762.0 | 234.9 | - | 501.6 | 660.4 | 717.6 | 736.6 | 1863 | 190 | |

| 32 | 812.8 | 812.8 | 234.9 | - | 552.5 | 711.2 | 768.4 | 787.4 | 1863 | 190 | |

| 34 | 863.6 | 863.6 | 234.9 | - | 603.2 | 762.0 | 819.1 | 838.2 | 1863 | 190 | |

| 36 | 914.4 | 914.4 | 234.9 | 654.1 | 812.8 | 869.9 | 889.0 | 1863 | 190 | ||

| 40 | 1016.0 | 1016.0 | 234.9 | - | 755.6 | 914.4 | 971.5 | 990.6 | - | - | |

| 42 | 1066.8 | 1066.8 | 234.9 | - | 806.5 | 965.2 | 1022.4 | 1041.4 | - | - | |

| 48 | 1219.2 | 1219.2 | 234.9 | - | 958.9 | 1117.6 | 1174.8 | 1193.8 | - | - | |

| 60 | 1524 | 1524 | 234.9 | 596.6 |

958.9 | 1422.4 |

1479.6 | 1498.6 | - | - | |

*For special size, contact our sales staff

*Changes may be made without notice for improved quality, environment, and safety, without affecting function or mounting

*Manufactured under ISO9001:2015, ISO14001 and OHSAS 18000 certified factory

*Under Japanese supervision with Japanese standard quality

Design by Web Design Indonesia